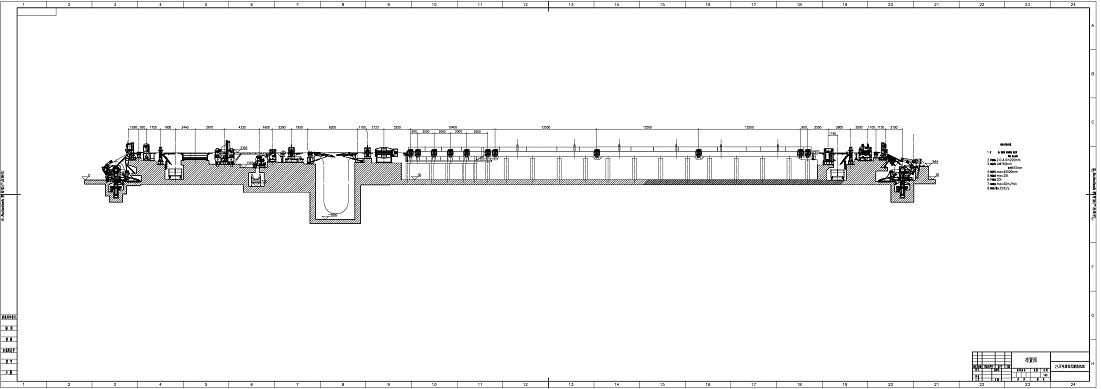

Pickling Line

Name: Pickling

Process flow

The coil needed to acid pickling is hung on the entry coil deposit saddle by crane, and the coil will be transported to preparation station by coil car, then transport to the drum of pay-off reel after head cutting treatment. Coil car back to the specified saddle. And also carry out coil height and width automatic centering during loading coil.

The line automatic decelerates and strip tail leave away pay-off reel drum when the previous coil rapid pickling finished. The line prepares to receive new coil.

The new coil automatic loads on the pay-off reel. Reversal point jogs the pay-off reel makes the strip head located on the coil where suit for uncoiling, press roll screw down and hold down the strip head. Joint jogging pay-off reel, swing table lifting, stretch out coil opening machine, make the strip head enter into opened pinch roll straightener, make the strip head centering through side guide roll, screw down the top pinch roll of pinch roll straightener. Side guide roll rapid open, coil opening machine reset, screw down the anti-bending roll. Joint jogging the pay-off reel and pinc straightener, the strip head is sent to entry head cut shear. If need, manual cut unqualified strip head. Then jogging send to corner cut side, to cut the two angle ends of strip head, so that easy for threading.

Start “ automatic threading” button, making the strip successively automatic pass pickling tank, cleaning tank with setting threading speed, after the strip pass through hot air dryer, edge blowing device carry out edge blowing. Strip pass through 1# pinch roll, exit looper swing table (when the strip tail pass through looper swing table, the swing table uprise), before the strip reaches the centering device, the speed will reduce to jogging speed, after through this centering device centering, the centering device close, the strip through closed 2# pinch roll arrives at phototube which at the back of 2# pinch roll. Exit looper swing table automatic down, 2# pinch roll continuous running with jogging speed, due to the 2# pinch roll speed and entry section speed is different, the strip fill the looper, when the strip fill looper to the synchronization limit, the entry section and 2# pinch roll speed synchronization.

The strip pass through the disc shear, the scrap cut by disc shear is sent to scrap shear along chute. The scrap through belt conveyor to waste scrap car and lifted away. The strip through the 2 roll of three roll bridle device, and stop at phototube which before exit deflector pinch roll. Automatic threading end (if strip shape is not good, or appear fault during automatic threading process can adopt the manual threading)

The exit section equipment jogging, the strip head through exit deflector roll insert in the jaw of tension reel. The tension reel wind 2-3 circles with low speed, down the 2# roll of 3-roller tension device, the threading process finished. The line raising speed to setting speed to carry out production.

During threading process, all equipments before looper pit use 5-roll pinch straightening machine speed for reference.

When normal pickling, the whole line use 1# pinch roll as speed reference. The unit entrance section and the exit section (the looping pit is bounded) speed synchronous and controlled by 4 groups phototube which installed in looper pit. The entry section speed reference is 1# pinch roll, exit section speed reference is 2 roll of 3-roll bridle device.

The unit is provided with strip automatic tracking system, ensure automatic threading and automatic tail process smooth.

No. 2 pinch roll with CPC automatic control. In order to ensure the strip centering enter into the trimming shear.

The tension reel adopts EPC system automatic edge coiling. The transverse offset 150mm

Name: Recoiling Line

Receiving and processing steel coil before steel coil package and delivery, make the steel coil meets customer's requirements. The recoiling Line main

function: the defective parts of steel coil removing, scrap edge removing, steel strip inspection,tension straighten of steel strip, steel strip oiling ,subsection,

bundling and weigh etc.

Process Flow

Coil loading car - Payoff reel - 1#Shearing and pinch device- Entry centering device- welderExit centering device- 1 #Pinch roll - Steering device- Side guide device- Circle shearing Scrap coiler - Deburring roll- Entry bridle roll (4-high) - Tension leveler- Exit bridle roll (4-high)- inspection table- Electrostatic oiler- 2#Shearing pinch device- Deflector roll ----- Tension reel- coil unloading car- Wrapper

Edge Milling Machine

Custom Design

We supply custom design for your request.

One Stop Solution

We can supply the turkey support for the whole line technology including the machine and processing with all necessary.

Forming Type

You can choose JCOE, UOE, or Bending Forming.

Service

All lift service

.

.