Bevelling machine

Thickness: Max 40mm

Length: 12000mm

Degree: 30--45

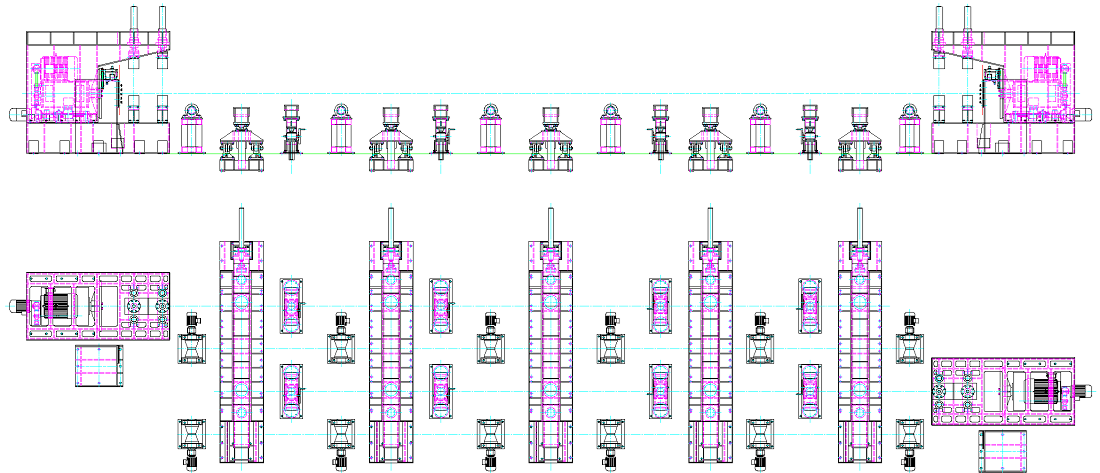

Equipment composition and Description

The flat head bevelling machine is composed of left and right flat head machine hosts and double station pipe transport vehicle; The main machine of the left and right flat head machine adopts the head to head arrangement, which is composed of fixture, headbox, cutter head, equipment base, fast feed drive system, spindle drive system, large travel drive device, guide rail, etc.

The clamp adopts upper and lower semicircle clamps, and the oil cylinder drives the opening and closing of the clamp; The headstock box body is a frame welding structure, with a main shaft inside, and the lower part is placed on the equipment base; The equipment base is also a frame welded structure, which is used to support the headbox and is placed on the guide rail; The cutter head is installed on the spindle of the headstock, and flat head cutter and bevelling cutter are installed on the cutter head; The fast feed and work feed drive system is composed of servo motor and ball screw, which is used to drive the cutter head and work feed by the headbox.

This system configuration makes the headbox run smoothly and have little vibration; The spindle drive system is composed of spindle drive motor, belt transmission mechanism and belt tensioning mechanism, which is used to provide driving force for the cutter head; The large travel driving device is used to adjust the basic position of the headbox when the length of the steel pipe changes, drive the headbox to move forward quickly, and cover the end of the steel pipe with a clamp; The guide rail is used to carry the headbox, so that the travel of the headbox matches the length of the steel pipe; The double station pipe transport vehicle is used to transport the steel pipe to be processed into the flat head machine and transport the processed steel pipe out of the flat head machine.

The pipe transport vehicle is driven by gear rack transmission and variable frequency motor, which can accelerate and decelerate evenly to avoid pipe falling. It runs at high speed and improves equipment efficiency.

Stainless Steel Pipe Facing and Beveling Machine

Diameter: 1219mm

Pipe Facing and Beveling Machine

Pipe Facing and Beveling Machine

Pipe Facing and Beveling Machine

Faced and Beveled Tube

Custom Design

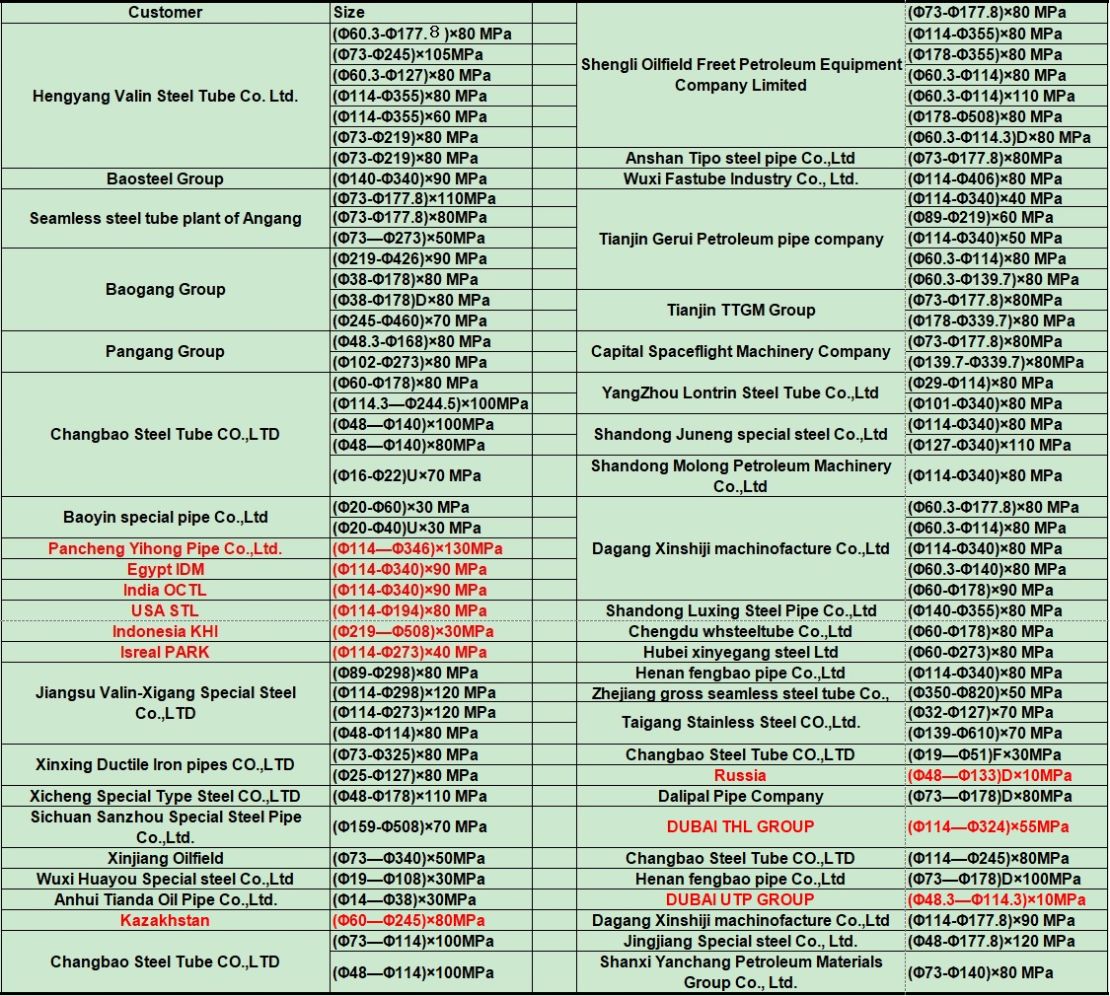

We supply custom design for your request.

High quality pipe end shape

High precision of the degree for all API standard request, no butt.

Efficient working mode

You can choose two pipes, four pipes and six pipes one time.

Service

All lift service

.

.