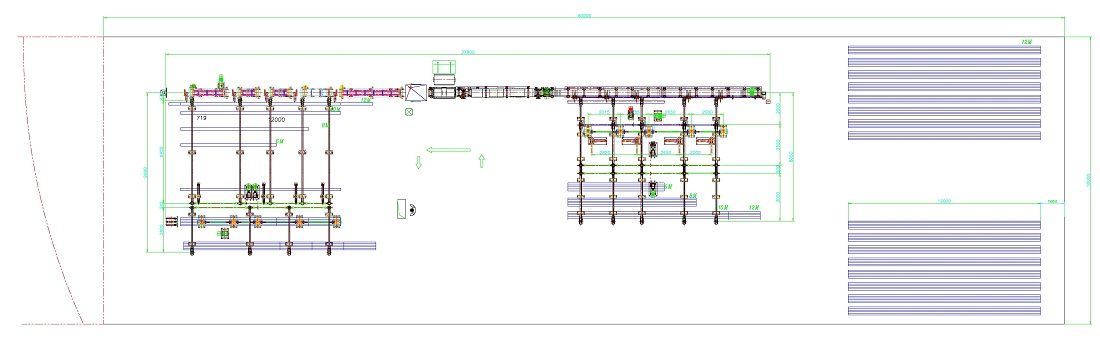

Steel Pipe Oil Coating Line

1 Process

High-pressure mist spraying machine is used for oiling, and the steel pipe is sprayed through the inner cylinder, and 6 spray guns are installed on the inner cylinder in a 360° direction to realize the oiling of the outer wall of the steel pipe.

The spray mark adopts the gantry beam type spray mark, the steel pipe is on the drying bench, and the large gantry beam spray mark bracket with the nozzle moves linearly along the steel pipe to realize the steel pipe spray mark.

The exhaust gas treatment adopts the catalytic combustion treatment system using the "dry paint mist filter + activated carbon adsorption and desorption concentration + catalytic combustion" treatment process, which can effectively treat the exhaust gas pollutants generated by the spray booth, such as toluene, xylene, and non-methane total hydrocarbons.

Steel Pipe Oil Coating Line

Steel Pipe Oil Coating Line

Heating box

Coating pump

Drying bed

Custom Design

We supply custom design for your request. Online machine with your pipe mill.

High Speed and Automatic control

Coating and marking with automatic control

Recycled and Reused Paint

The paint utilization rate is greater than 98%, and the paint can be recycled and reused

Service

All lift service

.

.